Abstract

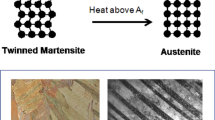

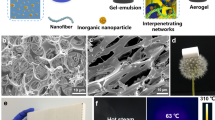

Ni40Ti50Cu10 foams were replication cast into a porous SrF2 preform. This space holder is chemically stable in contact with liquid and solid Ni40Ti50Cu10, but can be removed by dissolution in nitric acid. A Ni40Ti50Cu10 foam with 60 pct porosity exhibits low stiffness (1 to 13 GPa) and large recoverable strains (~4 pct) during cyclical compression testing at 311 K (38 °C), within the superelastic range based on calorimetry results. This is the first time that replication casting is used to create an open foam of a NiTi-based shape-memory alloy, due to difficulties associated with the high reactivity and strong contamination tendency of the melt. Casting NiTi-based shape-memory alloy foams enable the economical production of porous actuators, energy absorbers, and biomedical implants with complex shapes.

Similar content being viewed by others

References

T. Duerig, A. Pelton, and D. Stockel: Mater. Sci. Eng. A, 1999, vols. 273–275, pp. 149–60.

N.B. Morgan: Mater. Sci. Eng. A, 2004, vol. 378 (1–2), pp. 16–23.

W. Cai, X.L. Meng, and L.C. Zhao: Curr. Opin. Solid State Mater. Sci., 2005, vol. 9 (6), pp. 296–302.

C. Grossmann, J. Frenzel, V. Sampath, T. Depka, and G. Eggeler: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 2530–44.

J. Frenzel, J.A. Burow, E.J. Payton, S. Rezanka, and G. Eggeler: Adv. Eng. Mater., 2011, vol. 13 (4), pp. 256–68.

J. Van Humbeeck: Mater. Sci. Eng. A, 1999, vols. 273–275, pp. 134–48.

J. Frenzel, Z. Zhang, Ch. Somsen, K. Neuking, and G. Eggeler: Acta Mater., 2007, vol. 55 (4), pp. 1331–41.

Z. Zhang, J. Frenzel, K. Neuking, and G. Eggeler: Acta Mater., 2005, vol. 53 (14), pp. 3971–85.

A. Bansiddhi and D.C. Dunand: Acta Biomater., 2008, vol. 4 (6), pp. 1996–2007.

S.A. Shabalovskaya: Bio-Med. Mater. Eng., 2002, vol. 12, pp. 69–109.

G. Ryan, A. Pandit, and D.P. Apatsidis: Biomaterials, 2006, vol. 27 (13), pp. 2651–70.

C.E. Wen, J.Y. Xiong, Y.C. Li, and P.D. Hodgson: Phys. Scripta, 2010, vol. T139, paper no. 014070, pp. 1–8.

A. Bansiddhi and D.C. Dunand: Intermetallics, 2007, vol. 15 (12), pp. 1612–22.

A. Bansiddhi and D.C. Dunand: J. Mater. Res., 2009, vol. 24 (6), pp. 2107–17.

A. Bansiddhi and D.C. Dunand: Adv. Eng. Mater., 2011, vol. 13 (4), pp. 301–05 .

M. Sugiyama, S.K. Hyun, M. Tane, and H. Nakajima: High Temp. Mater. Process., 2007, vol. 26, pp. 297–301.

L.P. Lefebvre, J. Banhart, and D.C. Dunand: Adv. Eng. Mater., 2008, vol. 10 (9), pp. 775–87.

J. Banhart: Adv. Eng. Mater., 2006, vol. 8 (9), pp. 781–94.

J. Frenzel, Z. Zhang, K. Neuking, and G. Eggeler: J. Alloys Compd., 2004, vol. 385 (1–2), pp. 214–23.

J. Frenzel, E.P. George, A. Dlouhy, Ch. Somsen, M.F.X. Wagner, and G. Eggeler: Acta Mater., 2010, vol. 58 (9), pp. 3444–58.

A.H. Brothers, R. Scheunemann, J.D. DeFouw, and D.C. Dunand: Scripta Mater., 2005, vol. 52, pp. 335–39.

Y. Boonyongmaneerat and D.C. Dunand: Adv. Eng. Mater., 2008, vol. 10 (4), pp. 379–83.

M. Chmielus, X.X. Zhang, C. Witherspoon, D.C. Dunand, and P. Müllner: Nat. Mater., 2009, vol. 8 (11), pp. 863–66.

F. Diologent, E. Combaz, V. Laporte, R. Goodall, L. Weber, F. Duc, and A. Mortensen: Scripta Mater., 2009, vol. 61 (4), pp. 351–54.

Y. Conde, J.F. Despois, R. Goodall, A. Marmottant, L. Salvo, C. San Marchi, and A. Mortensen: Adv. Eng. Mater., 2006, vol. 8 (9), pp. 795–803.

R. Zarnetta, R. Takahashi, M.L. Young, A. Savan, Y. Furuya, S. Thienhaus, B. Maaß, M. Rahim, J. Frenzel, H. Brunken, Y.S. Chu, V. Srivastava, R.D. James, I. Takeuchi, G. Eggeler, and A. Ludwig: Adv. Funct. Mater., 2010, vol. 20 (12), pp. 1917–23.

A. Biscarini, B. Coluzzi, G. Mazzolai, F.M. Mazzolai, and A. Tuissi: J. Alloys Compd., 2003, vols. 356–357, pp. 669–72.

F.M. Mazzolai, A. Biscarini, B. Coluzzi, G. Mazzolai, E. Villa, and A. Tuissi: Acta Mater., 2007, vol. 55 (13), pp. 4243–52.

O. Mercier and K. Melton: Metall. Trans. A, 1979, vol. 10A, pp. 387–89.

K.P. Gupta: J. Phase Equilib., 2002, vol. 23 (6), pp. 541–47.

J. Khalil Allafi, X. Ren, and G. Eggeler: Acta Mater., 2002, vol. 50 (4), pp. 793–803.

N. Frantz-Rodriguez, A. Bosseboeuf, E. Dufour-Gergam, V. Stambouli-Séné, G. Nouet, W. Seiler, and J.-L. Lebrun: J. Micromech. Microeng., 2000, vol. 10 (2), p. 147.

R.W. Cahn: Adv. Mater., 1991, vol. 3 (12), pp. 628–29.

J. Mentz, J. Frenzel, M.F.-X. Wagner, K. Neuking, G. Eggeler, H.P. Buchkremer, and D. Stoever: Mater. Sci. Eng. A, 2008, vol. 491, pp. 270–78.

Y. Matsumoto, A.H. Brothers, S.R. Stock, and D.C. Dunand: Mater. Sci. Eng. A, 2007, vol. 447 (1–2), pp. 150–57.

A.J. Neurohr and D.C. Dunand: Acta Biomater., 2011, vol. 7 (4), pp. 1862–72.

A.J. Neurohr and D.C. Dunand: Acta Mater., 2011, vol. 59 (11), pp. 4616–30.

A. Yawny, M. Sade, and G. Eggeler: Z. Metallkd., 2005, vol. 96, pp. 608–18.

L.J. Gibson and M.F. Ashby: Cellular Solids: Structure and Properties, Cambridge University Press, Cambridge, United Kingdom, 1997.

D. Dunand, D. Mari, M. Bourke, and J. Roberts: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2820–36.

Acknowledgments

The authors acknowledge funding by the Deutsche Forschungsgemeinschaft (DFG) through Subproject C7 of the Collaborative Research Center SFB 459 (with additional funding from the German state of North Rhine-Westphalia and Ruhr-Universität Bochum). MLY also acknowledges support by the Alexander von Humboldt Foundation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 19, 2011.

Rights and permissions

About this article

Cite this article

Young, M.L., DeFouw, J.D., Frenzel, J. et al. Cast-Replicated NiTiCu Foams with Superelastic Properties. Metall Mater Trans A 43, 2939–2944 (2012). https://doi.org/10.1007/s11661-011-1060-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-1060-x