Abstract

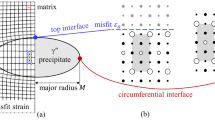

Assuming ideal plastic behavior for an isotropic matrix containing a misfitting spherical precipitate, the total amount of work expended during elasto-plastic deformation is calculated and compared with the total strain energy in the corresponding pure elastic state. For precipitates larger than one micron (µm), the effective yield stress is taken as the macroscopic yield stress while for smaller precipitates, size-dependent yield stresses are obtained from the Ashby-Johnson model. In the case of coherent submicron precipitates, the effective yield stress becomes the theoretical yield strength and thus plastic relaxation is not possible unless the transformation stress is extremely large. For incoherent submicron precipitates, the effective yield stress is approximately inversely proportional to the precipitate radius,r. Hence plastic relaxation again is not possible whenr < 10 nm, but whenr ≃100 nm the strain energy can decrease by 10 ∼ 40 pct at a misfit of 3 pct. For supra-micron particles, however, the ratio of the effective yield stress to the shear modulus becomes 10−3 or less, and plastic relaxation can reduce the strain energy by factors of 3 to 15 at misfits of 1 to 3 pct. Under this circumstance, the plastic zone becomes wide, its radius ranging from 3 to 5r.

Similar content being viewed by others

Abbreviations

- a :

-

spherical precipitate radius

- e] r :

-

radial strain component

- e] pr :

-

radial plastic strain component

- e] θ :

-

tangential strain component

- e] pθ :

-

tangential plastic strain component

- K :

-

bulk modulus of the matrix phase

- K * :

-

bulk modulus of the precipitate phase

- r p :

-

plastic zone radius

- u :

-

radial displacement

- α :

-

equal to (l +v)/3(1-v)

- β :

-

constrained displacement parameter

- γ :

-

equal toK */K

- ε:

-

misfit parameter

- μ:

-

shear modulus of the matrix phase

- μ* :

-

shear modulus of the precipitate phase

- ν :

-

Poisson’s ratio of the matrix phase

- ν*:

-

Poisson’s ratio of the precipitate phase

- σe :

-

equivalent stress

- σr :

-

radial stress component

- σy :

-

yield stress of the matrix phase

- σθ :

-

tangential stress component

References

K. R. Kinsman, J. W. Sprys, and R. J. Asaro:Acta Metall., 1975, vol. 23, p. 1431.

J. M. Rigsbee and P. J. VanderArend: Formable HSLA and Dual-Phase Steels, A. T. Davenport, ed., p. 58, TMS-AIME, New York, NY.

Y. Y. Earmme, W. C. Johnson, and J. K. Lee: unpublished research, Michigan Technological University, Houghton, MI, 1980.

M. F. Ashby and L. Johnson:Philos. Mag., 1969, vol. 20, p. 1009.

J. W. Christian:The Theory of Transformations in Metals and Alloys—Part I, 2nd ed., p. 200, Pergamon Press, Oxford, 1975.

R. Hill:The Mathematical Theory of Plasticity, p. 97, Oxford University Press, London, 1950.

A. Mendelson:Plasticity—Theory and Application, p. 135, MacMillan, New York, 1968.

J. D. Eshelby:Prog. Solid Mech., 1961, vol. 2, p. 89.

D. M. Barnett:Scr. Metall., 1971, vol. 5, p. 261.

P. W. Bridgman:J. Appl. Phys., 1947, vol. 18, p. 246.

G. E. Dieter:Mechanical Metallurgy, p. 58, McGraw-Hill, New York, 1961.

G. C. Weatherly:Met. Sci., 1968, vol. 2, p. 237.

M. F. Ashby, S. H. Gelles, and L. E. Tanner:Philos. Mag., 1969, vol. 19, p. 757.

L. M. Brown, G. R. Woolhouse, and U. Valdré:Philos. Mag., 1968, vol. 17, p. 781.

L. M. Brown and G. R. Woolhouse:Philos. Mag., 1970, vol. 21, p. 329.

J. W. Matthews and S. Mader:Scr. Metall., 1972, vol. 6, p. 1195.

K. Jagannadham and E. G. Ramachandran:J. Appl. Phys., 1974, vol. 45, p. 2406.

F. A. McClintock and A. S. Argon:Mechanical Behavior of Materials, p. 118, Addison-Wesley, Reading, 1966.

G. C. Weatherly:Philos. Mag., 1968, vol. 17, p. 791.

H. Brooks:Metal Interfaces, p. 20, ASM, Metals Park, OH, 1952.

R. M. Rose, D. P. Ferriss, and J. Wulff:Trans. TMS-AIME, 1962, vol. 224, p. 981.

V. A. Philips:Trans. TMS-AIME, 1964, vol. 230, p. 967.

K. E. Easterling:Acta Polytech. Scand., 1967, chapt. 61.

J. K. Lee and W. C. Johnson:Scr. Metall., 1977, vol. 11, p. 477.

A. Kelly and R. B. Nicholson:Prog. Mater. Sci., 1963, vol. 10, p. 149.

H. I. Aaronson, J. K. Lee, and K. C. Russell:Precipitation Processes in Solids, p. 31, K. C. Russell and H. I. Aaronson, eds., TMS-AIME, New York, NY, 1978.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, J.K., Earmme, Y.Y., Aaronson, H.I. et al. Plastic relaxation of the transformation strain energy of a misfitting spherical precipitate: Ideal plastic behavior. Metall Trans A 11, 1837–1847 (1980). https://doi.org/10.1007/BF02655099

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02655099