Abstract

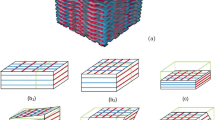

The clear multi-scale structure of composite textile reinforcements leads to develop continuous and discrete approaches for their forming simulations. In this paper two continuous modelling respectively based on a hypoelastic and hyperelastic constitutive model are presented. A discrete approach is also considered in which each yarn is modelled by shell finite elements and where the contact with friction and possible sliding between the yarns are taken into account. Finally the semi-discrete approach is presented in which the shell finite element interpolation involves continuity of the displacement field but where the internal virtual work is obtained as the sum of tension, in-plane shear and bending ones of all the woven unit cells within the element. The advantages and drawbacks of the different approaches are discussed.

Similar content being viewed by others

References

Advani SG (1994) Flow and rheology in polymeric composites manufacturing. Elsevier, Amsterdam

Saouab A, Bréard J, Lory P, Gardarein B, Bouquet G (2001) Injection simulations of thick composite parts manufactured by the RTM process. Compos Sci Technol 61:445–451

Mouritz AP, Bannister MK, Falzon PJ, Leong KH (1999) Review of applications for advanced three-dimensional fibre textile composites. Compos Part A 30:1445–1461

de Luycker E, Morestin F, Boisse P, Marsal D (2009) Simulation of 3D interlock composite preforming. Compos Struct 88:615–623

Tong L, Mouritz AP, Bannister MK (2002) 3D Fibre reinforced polymer composites. Elsevier Science, Oxford

Creech G, Pickett AK (2006) Meso-modelling of non-crimp fabric composites for coupled drape and failure analysis. J Mater Sci 41:6725–6736

Boisse P, Gasser A, Hagège B, Billoet JL (2005) Analysis of the mechanical behavior of woven fibrous material using virtual tests at the unit cell level. J Mater Sci 40:5955–5962

Dong L, Lekakou C, Bader MG (2001) Processing of composites: simulations of the draping of fabrics with updated material behaviour law. J Compos Mater 35:138–163

Hagège B, Boisse P, Billoët JL (2005) Finite element analyses of knitted composite reinforcement at large strain. European Journal of Computational Mechanics 14:767–776

Peng X, Cao J (2005) A continuum mechanics-based non-orthogonal constitutive model for woven composite fabrics. Compos Part A 36:859–874

Rogers TG (1989) Rheological characterisation of anisotropic materials. Composites 20:21–27

Spencer AJM (2000) Theory of fabric-reinforced viscous fluids. Compos Part A 31:1311–1321

ten Thije RHW, Akkerman R, Huétink J (2007) Large deformation simulation of anisotropic material using an updated Lagrangian finite element method. Comput Methods Appl Mech Eng 196:3141–3150

Yu WR, Pourboghrata F, Chungb K, Zampaloni M, Kang TJ (2002) Non-orthogonal constitutive equation for woven fabric reinforced thermoplastic composites. Compos Part A 33:1095–1105

Ben Boukaber B, Haussy G, Ganghoffer JF (2007) Discrete models of woven structures. Macroscopic approach. Compos Part B 38:498–505

Duhovic M, Bhattacharyya D (2006) Simulating the deformation mechanisms of knitted fabric composites. Compos Part A 37:1897–1915

Pickett AK, Creech G, de Luca P (2005) Simplified and advanced simulation methods for prediction of fabric draping. European Journal of Computational Mechanics 14:677–691

Zhou G, Sun X, Wang Y (2004) Multi-chain digital element analysis in textile mechanics. Compos Sci Technol 64:239–244

Durville D (2005) Numerical simulation of entangled materials mechanical properties. J Mater Sci 40:5941–5948

Durville D (2008) A finite element approach of the behaviour of woven materials at microscopic scale—11th Euromech-Mecamat conference—Mechanics of microstructured solids: cellular materials, fiber reinforced solids and soft tissues, Torino, Italia. arXiv:0804.2952v1 [cond-mat.soft]

Miao Y, Zhou E, Wang Y, Cheeseman BA (2008) Mechanics of textile composites: micro-geometry. Compos Sci Technol 68:1671–1678

Truesdell C (1955) Hypo-elasticity. J Ration Mech Anal 4:83–133

Xiao H, Bruhns OT, Meyers A (1998) On objective corotational rates and their defining spin tensors. Int J Solids Struct 35:4001–4014

Belytschko T, Liu WK, Moran B (2000) Nonlinear finite elements for continua and structures. Wiley, Chichester

Crisfield MA (1997) Non-linear finite element analysis of solids and structures. Wiley, Chichester

Badel P, Gauthier S, Vidal-Sallé E, Boisse P (2008) Rate constitutive equations for computational analyses of textile composite reinforcement mechanical behaviour during forming. Compos Part A. doi:10.1016/j.compositesa.2008.04.015

Hughes TJR, Winget J (1980) Finite rotation effects in numerical integration of rate constitutive equations arising in large deformation analysis. Int J Numer Methods Eng 15:1862–1867

Khan MA, Mabrouki T, Boisse P (2009) Numerical and experimental forming analysis of woven Composites with double dome benchmark. Proceedings Esaform 2009, Springer

Khan MA (2009) Numerical and experimental analyses of woven composite reinforcement draping using a hypoelastic behaviour. Ph.D. Thesis, INSA Lyon

Woven composites benchmark forum. http://www.wovencomposites.org/. Accessed 11 May 2009

Cao J, Akkerman R, Boisse P, Chen J et al (2008) Characterization of mechanical behavior of woven fabrics: experimental methods and benchmark results. Compos Part A 39:1037–1053

Lomov SV, Boisse P, De Luycker E, Morestin F, Vanclooster K, Vandepitte D, Verpoest I, Willems A (2008) Full-field strain measurements in textile deformability studies. Compos Part A 39:1232–1244

Buet-Gautier K, Boisse P (2001) Experimental analysis and modeling of biaxial mechanical behavior of woven composite reinforcements. Exp Mech 41:260–269

Spencer AJM (1984) Continuum theory of the mechanics of fibres-reinforced composites. Springer-Verlag, New York

Basar Y, Weichert D (2000) Nonlinear continuum mechanics of solids. Springer, Berlin

Ogden RW (1984) Non-linear elastic deformations. Wiley, New York

Truesdell C, Noll W (1965) The nonlinear field theories of mechanics. Edition Handbuch der Physik Vol. III. Spinger, Berlin

Aimène Y, Vidal-Sallé E, Hagège B, Sidoroff F, Boisse P (2009) A hyperelastic approach for composite reinforcement large deformation analysis. J Compos Mater. doi:10.1177/0021998309345348

Daniel JL, Soulat D, Dumont F, Zouari B, Boisse P, Long AC (2003) Forming simulation of very unbalanced woven composite reinforcements. Int J Form Process 6:465–480

Dumont F (2003) Expérimentations et modèles de comportement de renforts de composites tissés. Ph.D. Thesis, Paris VI University

Dridi S (2009) Modélisation du comportement mécanique des textiles par des lois hyperélastiques. Ph.D. Thesis, University of Monastir and INSA Lyon, to appear

Badel P, Vidal-Sallé E, Maire E, Boisse P (2009) Simulation and tomography analysis of textile composite reinforcement deformation at the mesoscopic scale. Compos Sci Technol 68:2433–2440

Grave G, Birkefeld K, von Reden T, Drechsler K, Kyosev Y, Rathjens A (2009) Simulation of 3D overbraiding—solutions and challenges. Second World Conference on 3D Fabrics and their Applications, Greenville

Nilakantan G, Keefe M, Gillespie JW, Bogetti TA (2009) Simulating the impact of multi-layer fabric targets using a multi-scale model and the finite element method. Recent advances in textile composites. Proceedings of the 9th International Conference on Textile Composites—TEXCOMP9), DEStech Publications, Inc., 506–515

Sapozhnikov SB, Forental MV, Dolganina NY (2007) Improved methodology for ballistic limit and blunt trauma estimation for use with hybrid metal/textile body armor. Proceedings of the Conference Finite element modelling of textiles and textile composites (CD ROM), St-Petersburg

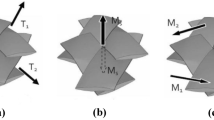

Boisse P, Zouari B, Daniel JL (2006) Importance of in-plane shear rigidity in finite element analyses of woven fabric composite preforming. Compos Part A 37:2201–2212

Hamila N, Boisse P, Sabourin F, Brunet M (2009) A semi-discrete shell finite element for textile composite reinforcement forming simulation. Int J Numer Methods Eng 79(12):1443–1466

Prodromou AG, Chen J (1997) On the relationship between shear angle and wrinkling of textile composite preforms. Compos Part A 28:491–503

de Bilbao E, Soulat D, Hivet G, Launay J, Gasser A (2008) Bending test of composite reinforcements. International Journal of Material Forming. doi:10.1007/s12289-008-0265-z

Launay J, Hivet G, Duong AV, Boisse P (2008) Experimental analysis of the influence of tensions on in plane shear behaviour of woven composite reinforcements. Compos Sci Technol 68:506–515

Lomov SV, Verpoest I (2006) Model of shear of woven fabric and parametric description of shear resistance of glass woven reinforcements. Compos Sci Technol 66:919–933

Sabourin F, Brunet M (1995) Analyses of plates and shells with a simplified 3 node triangular element. Thin-walled Struct 21:238–251

Onate E, Zarate F (2000) Rotation-free triangular plate and shell elements. Int Numer Methods Eng 47:557–603

Allaoui S, Boisse P, Chatel S, Hamila N, Hivet G, Soulat D (2009) Experimental and numerical analysis of a woven reinforcement forming process. Compos Part B, submitted

Hamila N, Boisse P, Chatel S (2008) Finite element simulation of composite reinforcement draping using a three node semi discrete triangle. International Journal of Material Forming 1:867–870. doi:10.1007/s12289-008-0-273-z

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

γ is the shear angle, γ = θ1–θ2 (Fig. 3). It is shown that a shear angle increment dγ gives stresses proportional to Gdγ in the stress computation scheme presented “Continuous approach 1: a hypoelastic model” (Eq. 3 to 11). That is important because the in-plane shear behaviour of a textile material is function of the shear angle (G is not a constant and depends on γ).

The polar rotation tensor and deformation gradient tensor are respectively:

\( {\lambda_\beta } \) is the deformed length of an initially unit fibre in the direction β. The right stretch tensor \( \underline{\underline {\mathbf{U}}} \) is given by the polar decomposition:

The symmetry of \( \underline{\underline {\mathbf{U}}} \) imposes

In the case of pure in plane shear (λ1 = λ2 = 1) or in the case of equal fibre elongations in warp weft directions, this equation becomes

In the case of most of the composite reinforcements, the fibre elongations are small and (31) can be considered.

Because the frames (\( {\underline {\mathbf{e}}_1},{\underline {\mathbf{e}}_2} \)), (\( {\underline {\mathbf{g}}_1},{\underline {\mathbf{g}}_2} \)), (\( {\underline {\mathbf{h}}_1},{\underline {\mathbf{h}}_2} \)) are orthonormal

Considering a shear increment \( {\text{d}}\gamma = {\text{d}}{\theta_1} - {\text{d}}{\theta_2} = {\text{d}}\varepsilon_{12}^{\text{g}} - {\text{d}}\varepsilon_{12}^{\text{h}} \), the Eqs. 31, 32, 33 lead to the specific form of the stress calculation Eq. 13:

Rights and permissions

About this article

Cite this article

Boisse, P., Aimène, Y., Dogui, A. et al. Hypoelastic, hyperelastic, discrete and semi-discrete approaches for textile composite reinforcement forming. Int J Mater Form 3 (Suppl 2), 1229–1240 (2010). https://doi.org/10.1007/s12289-009-0664-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-009-0664-9